Creative Visualisation

VizFX are specialists in providing powerful visual communication and digital twin products to give your project the wow factor

About Us

We are an agile creative visualisation and game development company providing high-quality photo-realistic computer-generated images (CGI), technical animations, robotic and digital twin simulations, 3D-printed joystick and pendant controllers, and virtual reality experiences.

Located in West Cumbria, at Lillyhall in Workington – just 5 miles from the Lake District National Park, and 15 miles from the Sellafield nuclear site.

Our neighbours are Energus, Lakes College, Gen2 and the National College for Nuclear, to name a few.

Our products visually communicate your process or product from concept to decommissioning in a powerful yet cost-effective way.

Our Services

Transform Your Projects with Creative Visual Communication and Digital Twin Products

If you want to make your project stand out and leave a lasting impression, then you need powerful visual communication and digital twin products. These solutions allow you to showcase your vision and bring it to life in stunning detail, capturing the imagination of your audience and leaving them in awe.

At VizFX, we are committed to providing our clients with a wide range of cutting-edge tools to take their projects to the next level.

-

Computer Generated Images (CGI)

-

Technical Animations

-

Robotic and Digital Twin Simulation

-

Virtual Reality

-

Industrial Process Optimisation

-

Aerial Film and Photography

-

3D Printing

Powerful visual communications

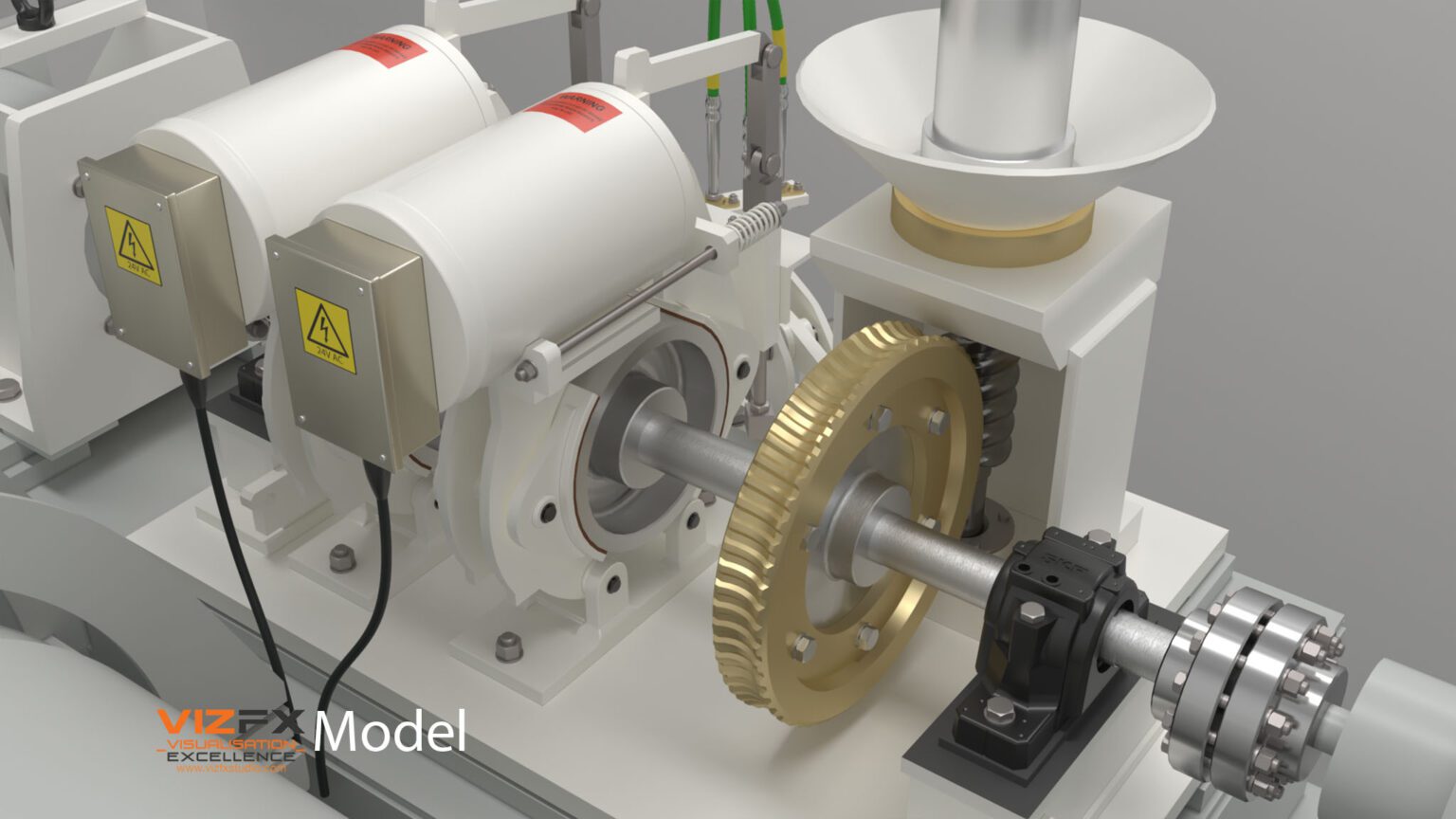

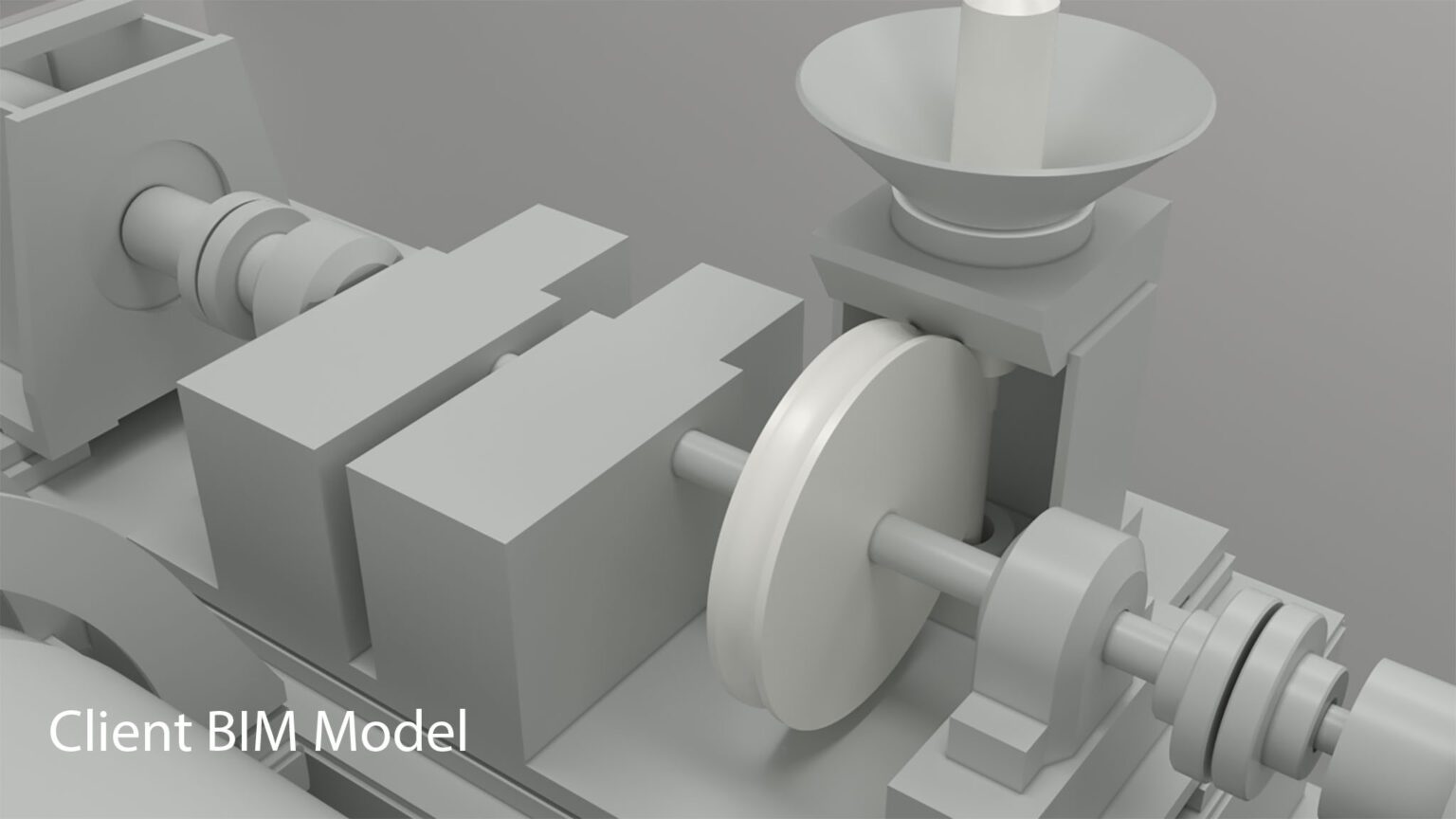

Photo-realistic visuals enable those viewing the images to better understand the content, bringing proposed developments to life, engaging with stakeholders, and giving opportunities to refine your design while costs are relatively low.

After

After Before

BeforePhoto-realistic animations

Your audience can see, understand, and familiarise themselves with your plant, project or process while it’s still in design, construction or commissioning. Photo-realistic animations give viewers the feeling that they are looking at the actual as-built or operational scene.

For training and/or plant familiarisations this is a great way of giving people a view around the plant before it is physically possible or potentially unsafe for them to do so.

Operator training and virtual commissioning

Using commercial game development technology, our virtual commissioning and industrial simulations power and drive digital twins of robots and electro-mechanical mechanisms – such as industrial robots, mast manipulators and bridge cranes – with huge benefits for operator training and virtual commissioning.

We have developed our own single and dual 6-axis industrial robot training simulator, utilising realistic Inverse Kinematics for teleoperation, to allow operators to drive the virtual robots in Axis, World and Tool-Centre-Point (TCP) mode. This is available for demonstration now in our office at Lillyhall.

We also have a Mast Manipulator and Bridge Crane simulators in our development pipeline, with the Mast Manipulator Simulator scheduled to be demonstratable in Q3 2025.

Utilise virtual reality to give your project a real sense of immersion and scale

Using commercial game development technology, your audience can virtually stand, sit, walk, look-around and interact within your plant, project or process, giving a real sense of immersion and scale that cannot be achieved by other tools.

Bring industrial processes to life through animation to make optimisation so much easier

Many processes are developed within Mechanical Flow Diagrams (2D block diagrams), consisting of sequential blocks of text describing start conditions, inputs, activities, and outputs. With the best endeavours and multiple reviews, complex processes can still be difficult to understand and optimise using 2D drawing tools. Animating the same process brings it to life and makes understanding and optimisation so much easier so that bottlenecks can be identified, opportunities for parallel or multi-tasking explored and significant improvements made, all before the process is built, let alone even in operation.

By example, we produced an animation of a filter change operation which must be carried out remotely, in a nuclear environment. We accurately modelled the relevant equipment, and noticed a filter lid park stand, whose sole function is to provide temporary support to a filter lid which had a mass of 99kg. The park stand material was specified as S355 high-strength structural steel, and had an approx. mass of 96kg.

Without going into design detail, there was a large bearing (or contact) area between the two parts, such that a relatively low compressive strength material would be adequate (with significant spare capacity) to support the filter lid. Manufacturing the filter lid park stand from steel (regardless of the grade) would necessitate the use of lifting equipment to move it into place, including the use of lifting eyes, being screwed in for lifting, and then removed prior to operation, by operators in suits and respirators, wearing double gloves, due to the radiological contamination hazard.

We suggested a change of material, to an engineering plastic, such as nylon or polypropylene. These could easily include machined ‘hand-holes’ to enable lifting and carrying, eliminating the need for lifting equipment, and therefore greatly reducing the time to carry out the task, and therefore the radiation dose uptake to the operator.

All of our products and services can utilise your existing 3D CAD models and 2D drawings, equipment manufacturer’s 3D & 2D CAD data, point cloud survey datasets, or be created natively by us, building physically accurate virtual models and digital twins. We utilise ‘game engine’ modelling workflows that ensure that models produced by us are optimised for high quality, no-lag virtual reality experiences.

Aerial surveys and cinematic, attention-grabbing clips

Using commercial drones, our drone operators can produce high-quality aerial film and photography including cinematic flyovers and pan shots. This can be utilised for aerial surveys or cinematic, attention-grabbing clips of your company’s premises.

All our drone operators are CAA (Civil Aviation Authority) qualified.

Accelerating Simulator Development with 3D Printing: Designing a Custom 6-Axis Robot Controller

We have a number of simulator projects planned for the next 12 – 18 months, with each requiring different input devices (variations of joystick and pendant controls). Not being able to source these controls in a timely manner would be a complete showstopper for these projects.

Taking a cue from “necessity is the mother of invention” – earlier this year, faced with a 3+ month wait for some joysticks – we decided to investigate the viability of designing our own robot controller, utilising 3D printing. 5-months and numerous prototypes later, we have our own superbly engineered 6-axis robot controller. This comprises a robust and ergonomic 3D printed enclosure, fitted with two 3-axis 3D printed joysticks, connected to a single integral USB game device interface card. All bought in components were selected based on being high-quality recognised brands (e.g. Honeywell sensors, Omron micro-switches, Igus bearings) and having good availability. Prototypes and working prototypes aside, we completed our first 6-axis robot controller while still waiting for delivery of the joysticks we originally ordered on a 3+ months lead time (now delayed 3 times and still haven’t arrived at time of writing).

The knowledge we have gained during this process can be applied to any other input device that we may need for future projects.

Our 3D print volume capability

- 5-tool multi-material 360mm x 360 mm x 360mm FDM

- 218mm x 123mm x 235mm Resin LCD Type

- We have a full range of engineering grade filaments and resins, plus associated threaded heat inserts and tooling.

Whatever your needs may be, our expert team is dedicated to working with you every step of the way to help you achieve your goals and bring your vision to life

With our innovative solutions and cutting-edge technology, you can rest assured that your project will have the wow factor that sets it apart from the rest.

Project Gallery

Contact Us

Looking to start your project? Contact our team today

No matter the scale of your project, our expert team is on hand to discuss your requirements and advise you on our wide range of services.

So drop us an email, complete our enquiry form or give us a call and let’s discuss how we’ll bring your next project to life.

Enquiry Form

"*" indicates required fields